Choose For Clamps, Round Bars, Pipes And Tubes, etc.!

About Us

Omaa Metal Sources is a brainchild of a hands-on group possessing proficient specialists in numerous domains such as designing, developing, quality control and management. We are supreme manufacturers and stockiest dealing in the quality-accredited range of Flanges, Gaskets, Fasteners, Pipes and Tubes and Instrumentation Fittings, etc.

Our manufacturing firm has been providing products of topmost quality according to the customers projects, standards, drawings and specifications. We are possessing up-to-date production facility that has been appropriately furnished since the business establishment with most technologically supreme tools and machinery for meeting orders requirements in the industry in the lesser time period. Our portfolio contains Stainless Steel Washer, EFW Pipes, Round Bars, Blind Flanges and many more industrial goods.

Our company has gained industrial fame through continually catering to the needs of industries such as Fertilizer Plants, Refrigeration, Pharmaceutical, Automobile, Power Plants, Chemical Plants, Sanitary & Plumbing, etc. We strive to be a fundamental choice in the cutthroat industry through serving high-quality based products to the customers. Our business renders world-known quality at the most appropriate price range in the industry.

Make your

enquiry now !

Talk to us! we will be glad to assist

you.

Product Gallery

-

90 Degree Elbow Buttweld Fitting -

45 Degree Elbow Buttweld Fitting -

180 Degree Elbow Buttweld Fitting -

Socket Weld 90 Degree Elbow -

Socket Weld 45 Degree Elbow -

Threaded Tee -

Slip On Flanges -

Socket Weld Flanges -

Blind Flanges -

Stainless Steel Washer -

Seamless Pipes -

Saw Pipes -

EFW Pipes -

Round Bars -

Forged Bars -

Copper Bars -

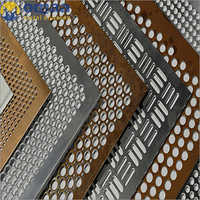

Perforated Sheets -

Hairline Sheets -

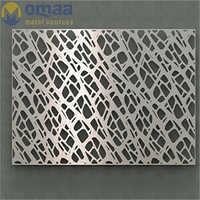

Designer Sheets -

SS Flexible Hoses Pipes -

Corrugated Gaskets -

Solid Gaskets -

Stainless Steel Valves -

Alloy Steel Valves -

Heavy Duty Pipe Hanger Clamp -

Floating Flange Expansion Joint -

Flexible Metallic Pump Connectors -

Threading Outlets -

Socket Weld Outlets -

Weld Outlets -

SS Instrumentation Tube Fittings -

Stainless Steel High Pressure Pipe Fittings -

Manifold Valves -

SS Coupling

Quality Policy

Our entity has been complying with national and international quality regulations and norms since business emergence. We are managing our operations abiding by the customers quality standards to fulfill their aspirations in the most reliable manner in the industry. We apply crucial training, instructions and methods for assuring finest improvements in the quality management systems.

Safety Policy

- Accident-free environment for everyone in the business space

- Continual safety education as well as certification programs

- Regular safety training

- Safety awareness meetings

- Safety Bulletin

- Safety records maintaining

- Zero accidents at business functioning

Our Philosophy

We are an outstanding vision of Mr. J.S. Chauhan, a man having impactful identity in the Indian Steel Industry, popularly known as a The Man of Steel. Banking on his leadership, insights and performance, business has managed to achieve the uppermost position in the challenging business line. Even today after his retirement, he tremendously contributes with his knowledge in making company attain remarkable fame in the industry.

Our present core management includes Mr. M J Chauhan (Company Director) and other many leaders possessing 4 decades based experience in the segment. The leading team showers a positive influence of its knowledge not just on other workers but on overall business. The two core factors which they believe are most powerful in business glory are support by the truest workforce and support of family and friends.

Journey In Brief

- 1994 to 2000: Launched New Technology

- 2000 to 2004: Attained 500 Projects Milestone

- 2004 to 2008: Started New Branch

- 2008 to 2021: Received Best Manufacturer Award

Why Choose Our Company?

Our Vision: To obtain most dependable position in the market segment and perform as the remarkable partner for industrial projects in India and other markets of the world.

Our Mission: To nurture a supreme business affiliation by serving the premium-quality products, always.

Our Objectives: Right usage of resources to acquire optimum results. To surpass expectations of valuable customers by serving suitable quality products such as Blind Flanges, EFW Pipes, etc., within shortest time-frame.

Quality

Inspection and Documentation Records, QCP

Basic materials are obtained from market-popular vendors with correlated test certificates. After bringing them at our factory, each of the material is cross check accurately with TC provided by vendors and sample. The full lot is sent to the well known lab for the testing.

Before manufacturing every item is appropriately stamped with related heat no. as well as the amt. Of pipes or raw materials accurately debited from stock based book. Dies are examined from time to time and if they appear to be over-sized the rectification is done prior production. All internal testing stages wise a proper book is kept wherein daily basis progress of production dimensions are written and seen that they are under permissible limits.

During production, examination is conducted to know if there any deformities or cracks are present and if found then the item is immediately rejected. After manufacturing is done, 100% dimensional check is executed. The samples of the batch are given for the purpose of testing for micro as well as chemical analysis and on achieving satisfaction report then only items are well stored and maintained as finished goods.

For WPW or ERW Fittings

Welder is made qualified by the end of any renowned consultant or party 2 years. Welding is executed by TIG utilizing the accurate filler wire of Advani Make. Initial Vee preparation is conducted as well as complete setup for the purpose of Vee preparation and root gap is examined before being released for the welding purpose.

After root run back chip DP test is conducted in the accurate manner, release is done for welding. The fitting then at last is dress up and solution annealed after which radiography pertaining to the joints is conducted with proper identification.

Our quality assurance unit is reliably outfitted with some of the following:

- Ultrasonic Testing Instrument

- Microscope for IGC Testing

- Digital Hardness Testing Instrument

- Electrometer

- PMI Instrument, etc...

Destructive Tests

- Elongation test

- Flange test

- Flatten test

- Grain size test

- Hardness test

- Intergranular corrosion test

- Mechanical property tests

- Metallographic examination

- PMI/ Chemical composition

- Tensile test

- Yield point test

- other numerous tests as asked by client

Non-Destructive Tests

- Air pressure test

- Dimension examination

- Eddy current test

- Hydrostatic test

- PMI test

- Radiographic examination

- Surface examination

- Ultrasonic test

|

OMAA METAL SOURCES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |